MTL is the UK’s 1st and only Strenx® Certified Fabricator. The Strenx® Certified Fabricator Network is an exclusive initiative designed to recognise and promote excellence in the field of high strength steel fabrication.

The Strenx® Certified Fabricator Network connects a select group of fabricators known for supplying OEMs with cutting-edge steel components and pre-fabricated structures. Their demonstrated skill and expertise with SSAB’s Strenx® performance steel ensure high-quality results. Equipped with experience and workshop tools, Strenx® Certified Fabricators process Strenx performance steel to the highest standards, with access to technical support from SSAB on material choice and manufacturing techniques.

MTL Advanced is proud to announce that they are the UKs first and only Strenx® Certified Fabricator.

With various quality accreditations and many years’ experience working with this material, we are able to supply and manufacture Strenx® 700 plates in different shapes, sizes and thicknesses to satisfy the needs of our customers.

S 900 is a structural steel and is hot-rolled, specifically made for cold forming and has good cutting performance ideal for load-bearing structures where low-weight is required.

Strenx® 1100 is a group of structural steel grades with a minimum yield strength of 1100 MPa, making it an ideal material for advanced lifting devices. Despite its strength, the material is surprisingly easy to weld and bend, which we offer in-house.

S1300 has a high impact toughness which provides for good resistance to fractures, making it the ideal material choice for load-bearing structures. S 1300 has excellent HAZ strength and toughness and can also be welded to other types of weldable steels using any conventional method of welding.

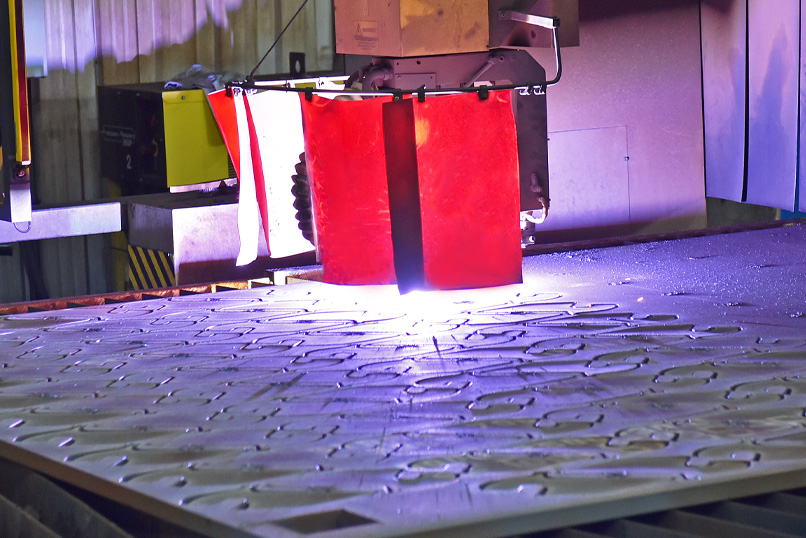

Due to our extensive manufacturing capabilities, we can laser/plasma cut, press, fabricate and machine Strenx® parts up to 700HB. We can also waterjet cut Strenx® to avoid a Heat Affected Zone (HAZ). As one of the UK’s largest Strenx® Stockholder, we can offer customers a fast turnaround due to our extensive stock on site in various grades and thicknesses.

Our Business Development Team can offer on-site visitation to provide expert advice, discuss your Strenx® requirements and help in the design optimisation stage of the project.

Large Format Laser Cutting: XXL Cutting Up to 14m x 3.3m. Waterjet Cutting: Up to 7.3m x 2.4m. Plasma Cutting: Up to 10m x 2.5m.

1 x Robotic Press Brake: XXL URSVIKEN 640 Tonne CNC Press 7.6m wide. 6 x Large Format Press Brakes: Up to 8m wide.

Welding Hardox: MTL proudly hold the title of the UK’s first and only Strenx Certified Fabricator, MTL exemplifies excellence in high-strength steel fabrication.

Due to our extensive manufacturing capabilities, we can laser/plasma cut, press, fabricate and machine Strenx® parts up to 700HB. We can also waterjet cut Strenx® to avoid a Heat Affected Zone (HAZ). As one of the UK’s largest Strenx® Stockholder, we can offer customers a fast turnaround due to our extensive stock on site in various grades and thicknesses.

Our Business Development Team can offer on-site visitation to provide expert advice, discuss your Strenx® requirements and help in the design optimisation stage of the project.

MTL excels in metal-based technology manufacturing, staying ahead of industry trends, providing outstanding customer service, and delivering exceptional quality and timely results.

Part of WEC Group