Laser Cutting

MTL are experts in laser profiling and have become a reputable global supplier of laser cut parts. Starting as a laser cutting company, it has remained at our core as we have gradually expanded to offer a wider range of services. Ideally located in Rotherham, Yorkshire, MTL has grown into one of the UK’s largest laser cutting companies.

Efficient Laser Profiling

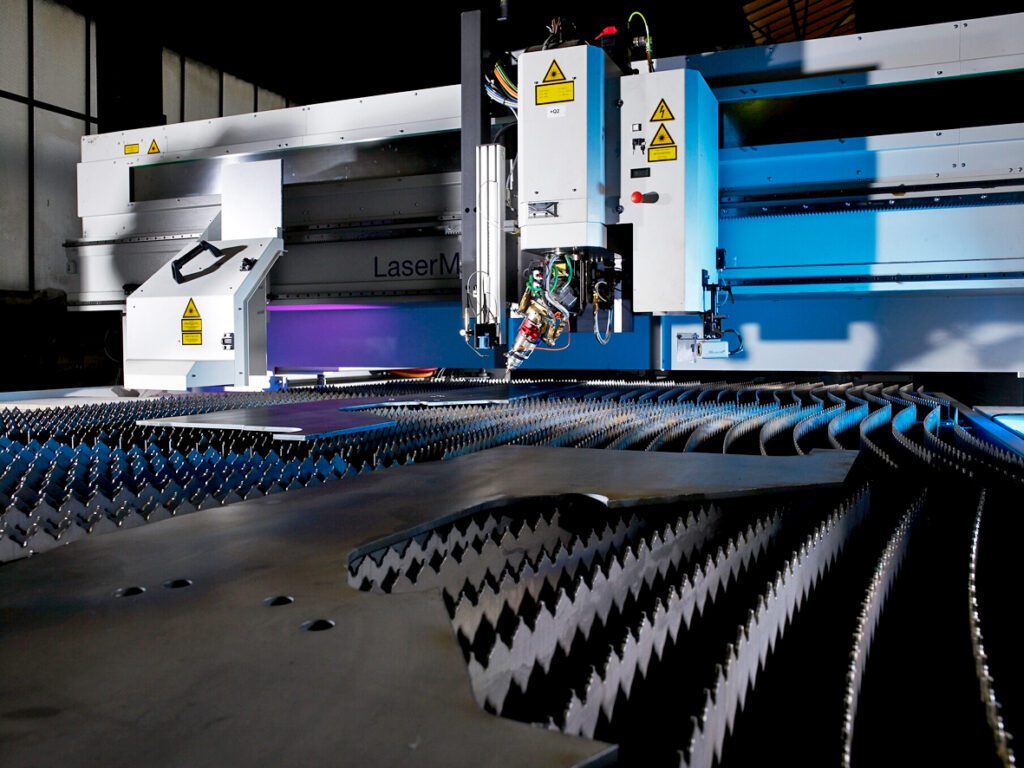

Our impressive 50,000 sq ft bay dedicated exclusively to cutting, houses 6 industry leading fibre laser cutting machines operating around the clock.

Our new LVD Taurus is the first of its kind in the UK, featuring a sizeable 14m x 3.3m bed and boasting 12KW cutting power. The new machines bevel cutting head also enables bevel cuts of up to 50 degrees which can cut various shapes and profiles and reduce weld prep times. This improves efficiency and productivity and in turn reduces costs and lead times for our customers.

Our lasers high-speed precision cutting capabilities can tackle thick plates up to 30mm. The machine is effective when used on tough metals including Hardox® and Strenx®.

Large Format Cutting

Our large format cutting cell specialises in the profiling of large parts up to 14m in length giving us the edge over our competitors and allowing us to produce large single piece components.

With 6 large format fibre laser cutting machines in-house, we can offer very competitive lead-times for all your cutting requirements, and we also specialise in the cutting and bending of tough metals including Armox®, Hardox® and Strenx® (formally known as Weldox®) up to 30mm thick to name but a few.

Investment in the very latest laser cutting technology

Our new LVD Taurus is the first of its kind in the UK, featuring a sizeable 14m x 3.3m bed and boasting 12KW cutting power. The new machine’s bevel cutting head also enables bevel cuts of up to 50 degrees which can cut various shapes and profiles and reduce weld prep times. This improves efficiency and productivity and in turn reduces costs and lead times for our customers.

Our lasers high-speed precision cutting capabilities can tackle thick plates up to 30mm. The machine is effective when used on tough metals including Hardox®, Strenx®, Armox®, S690QL, aluminium, stainless steel, mild steel and armour plates.

Materials

We hold a vast range of stock plate material in-house, whether it be for meeting a ballistic threat level specification to relining a bucket from Hardox plate.

Our relationship with the major steel mills in both Europe and the USA allows us to respond quickly to our customers’ requirements using some of the best materials on the market.

As the largest Hardox Wearparts Centre in the UK, we have a wealth of experience in manufacturing parts from abrasive resistant and high-strength steels, working on even the most demanding applications.

Specialist Steel

- Hardox®

- Strenx®

- Corten

- Zintec

- Raex

- Hastelloy

- Optisheen

- Cromweld

- Domex

- Titanium

- S690QL

- Copper

- Brass

Armoured Materials

- Armox®

- Mars

- Difender

- Armoured Titanium

- Armoured Aluminium

Mild Steel

- S275

- S355

- S355JR

- S355J2

- S355MC

- Galv/Galvanised Steel

Stainless Steel

- 304 stainless steel

- 316 stainless steel

- Polished stainless steel

- Brush finished stainless steel

- Patterned stainless steel

Aluminium

- Aluminium 1050

- Aluminium 5083

- Aluminium 6082

Trusted to Deliver

Ensuring On-Time In-Full Deliveries

At MTL Advanced, we’re continually seeking ways to improve our services and deliver greater value. That’s why we’ve implemented a cutting-edge Barcode Inventory Management System, designed to enhance the quality, speed, accuracy, traceability, and efficiency of our operations. Most importantly, this system enables us to deliver your orders On-Time In-Full, ensuring you get what you need exactly when you need it.

How it directly benefits you:

Implementing this advanced system is a testament to MTL Advanced’s commitment to innovation and efficiency. By leveraging the power of this revolutionary platform, we have enhanced our operational capabilities, reduce costs, and improve service delivery to our clients.

- Faster Turnaround Times: With real-time tracking and precise barcode scanning, we ensure the products you need are always in stock and ready for dispatch, minimising delays and streamlining your experience.

- On-Time In-Full: Ultimately, this system allows us to manage the movement of parts around the business with far greater efficiency. As a result, we can ensure the timely and complete delivery of your orders: On-Time In-Full, every time.

- Enhanced Traceability: Every item is fully traceable from the moment it enters our system, providing full visibility across the supply chain. This helps improve compliance, accountability, and transparency for you.

- Enhanced Accuracy: By automating barcode scanning and data entry, we significantly reduce manual errors. This leads to more accurate inventory records and better overall management.

- Informed, Efficient Decision-Making: Our new system provides detailed reports and analytics, helping us optimise stock levels and strategies to better meet your needs—so you benefit from faster, smarter service.

Why choose MTL?

MTL Advanced stands out as a premier choice for laser cutting services due to its commitment to cutting-edge technology and large-format cutting capabilities. With significant investment in the latest machinery, MTL Advanced is able to deliver precision and efficiency across a range of projects. Our most recent addition, the large format 12kw LVD Taurus, is a game-changer in the industry. This high-performance laser cutting machine offers large-format cutting capabilities up to 14m x 3.3m x 30mm thick, enabling MTL to handle oversized materials with ease and accuracy. Whether it’s complex designs or high-volume production, the Taurus ensures that even the largest sheets can be cut with exceptional precision, minimizing waste and reducing lead times.

MTL’s focus on innovation and investment in state-of-the-art technology means that clients benefit from shorter turnaround times and improved quality. By choosing MTL Advanced as your laser cutting provider, you are partnering with a company that values efficiency and on-time deliveries, ensuring your project is completed to the highest standards, on schedule, and in full.

Our Manufacturing Capabilities

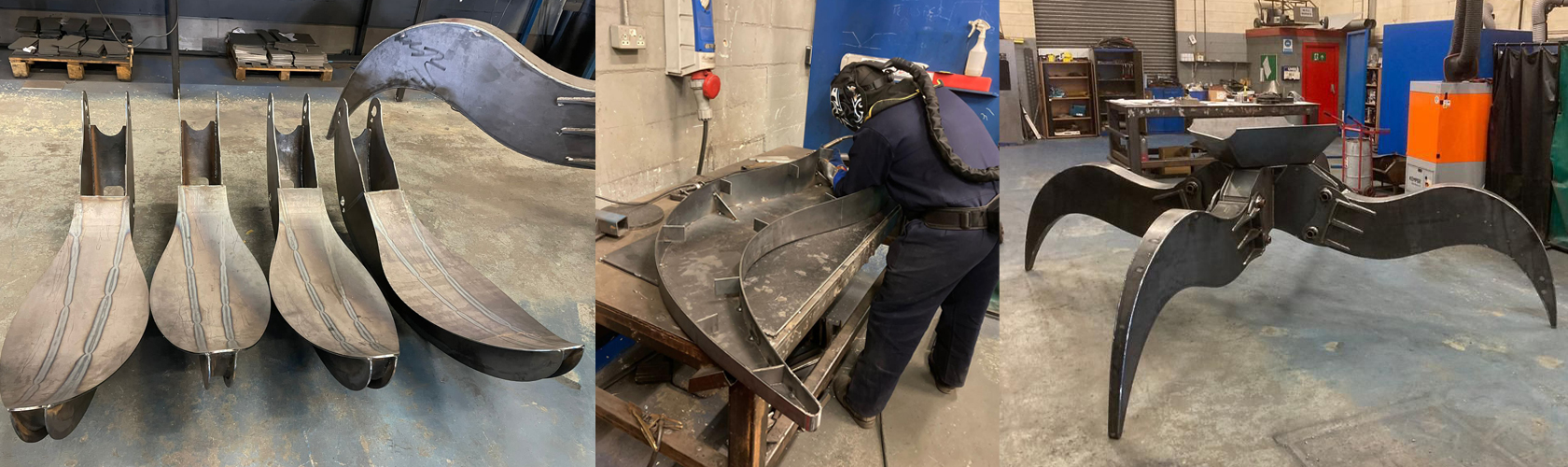

Fabrication & Assembly

MTL is recognised as a leading global supplier of fabricated components and holds an impressive range of approvals/standards for various grades of carbon steels and aluminium.

CNC Machining

MTL is a large scale manufacturing specialist with a wide range of capabilities. We continually invest in the highest quality CNC machinery throughout our facility.

Press Braking/Folding

MTL are experts in laser cutting and have become a reputable global supplier of laser cut parts. Starting as a laser cutting company, it has remained at our core as we have gradually expanded to offer a wide range of services.

Shotblasting

We provide in-house wet painting, shot blasting and powder coating services to a range of industries including defence, rail, automotive, oil and gas, recycling and many more.

Wet Painting

We offer professional in-house wet painting, shot blasting, and powder coating services to a diverse range of industries such as defense, rail, automotive, oil and gas, recycling and many others.

Contract Manufacturing

We provide services to a range of large OEM’s from leading industries including defence and security, construction and quarrying, recycling and rail.

Commitment to Quality