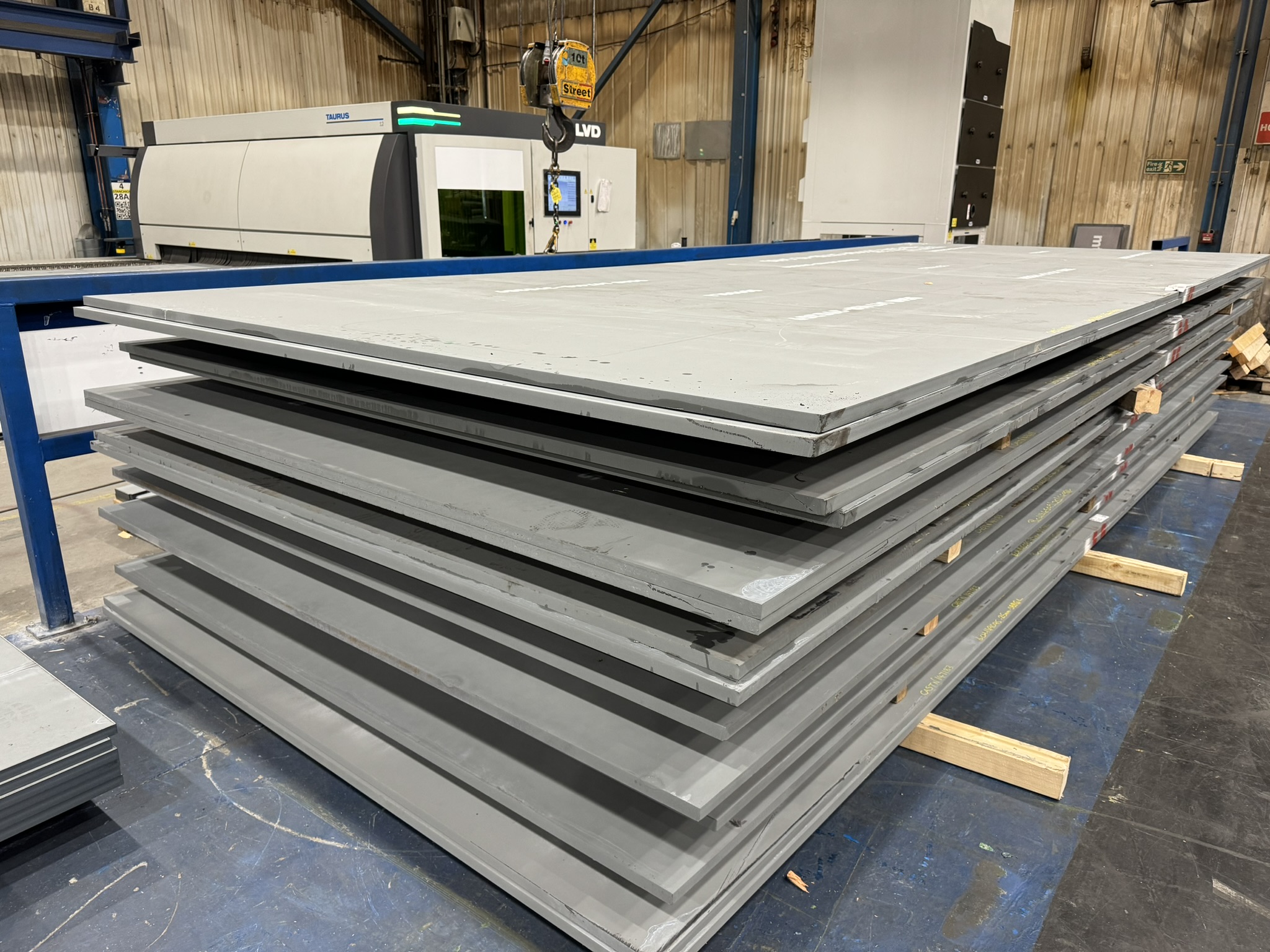

Strenx® 900

MTL Advanced Ltd is an official SSAB Strenx processor/stockholder for clients around the world. We have the capacity to complete all Strenx laser/plasma/waterjet cutting, bending/folding, fabrication and machining requirements at our 388,000 sq. ft. facility, in Rotherham, near Sheffield, Yorkshire, UK.

Strenx 900 Stockholder & Supplier

With various industry quality accreditations and many years’ experience working with this material, we are able to process Strenx plates in different shapes, sizes and thicknesses to satisfy the needs of our customers.

Due to our extensive in-house manufacturing capabilities, we can also machine, press parts up to 7.2m length and laser cut Strenx to the UK’s highest standards.

What are the benefits of Strenx 900?

Strenx 900 has a high impact toughness which provides for good resistance to fractures, making it the ideal material choice for load-bearing structures.

S 900 can also be welded to other types of weldable steels using any conventional method of welding.

What is Strenx 900?

S 900 is a structural steel with a minimum yield strength of 830-900 MPa depending on thickness/range. S 900 is hot-rolled, specifically made for cold forming and has good cutting performance ideal for load-bearing structures where low-weight is required.

Commitment to Quality