Strenx® 700

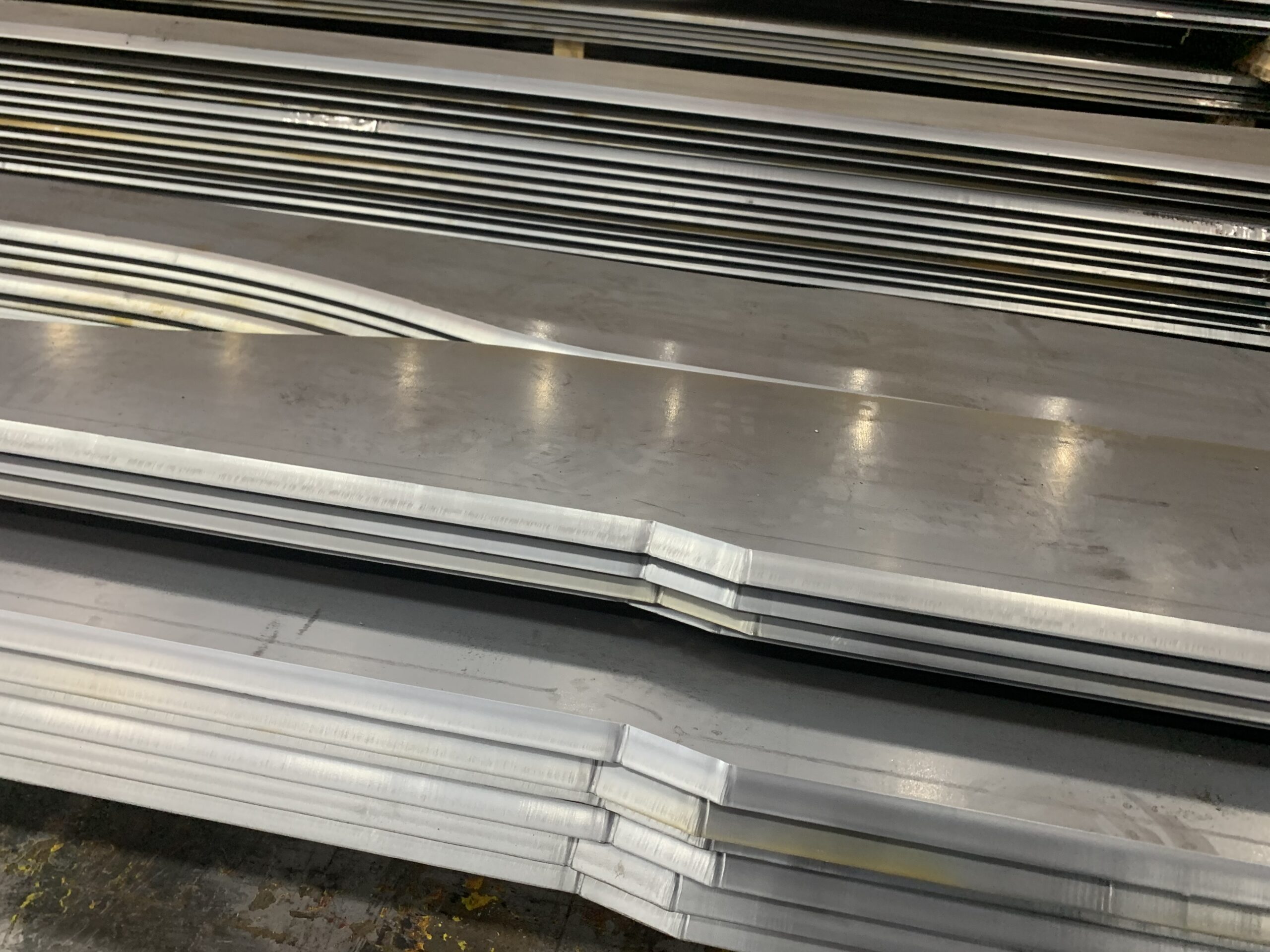

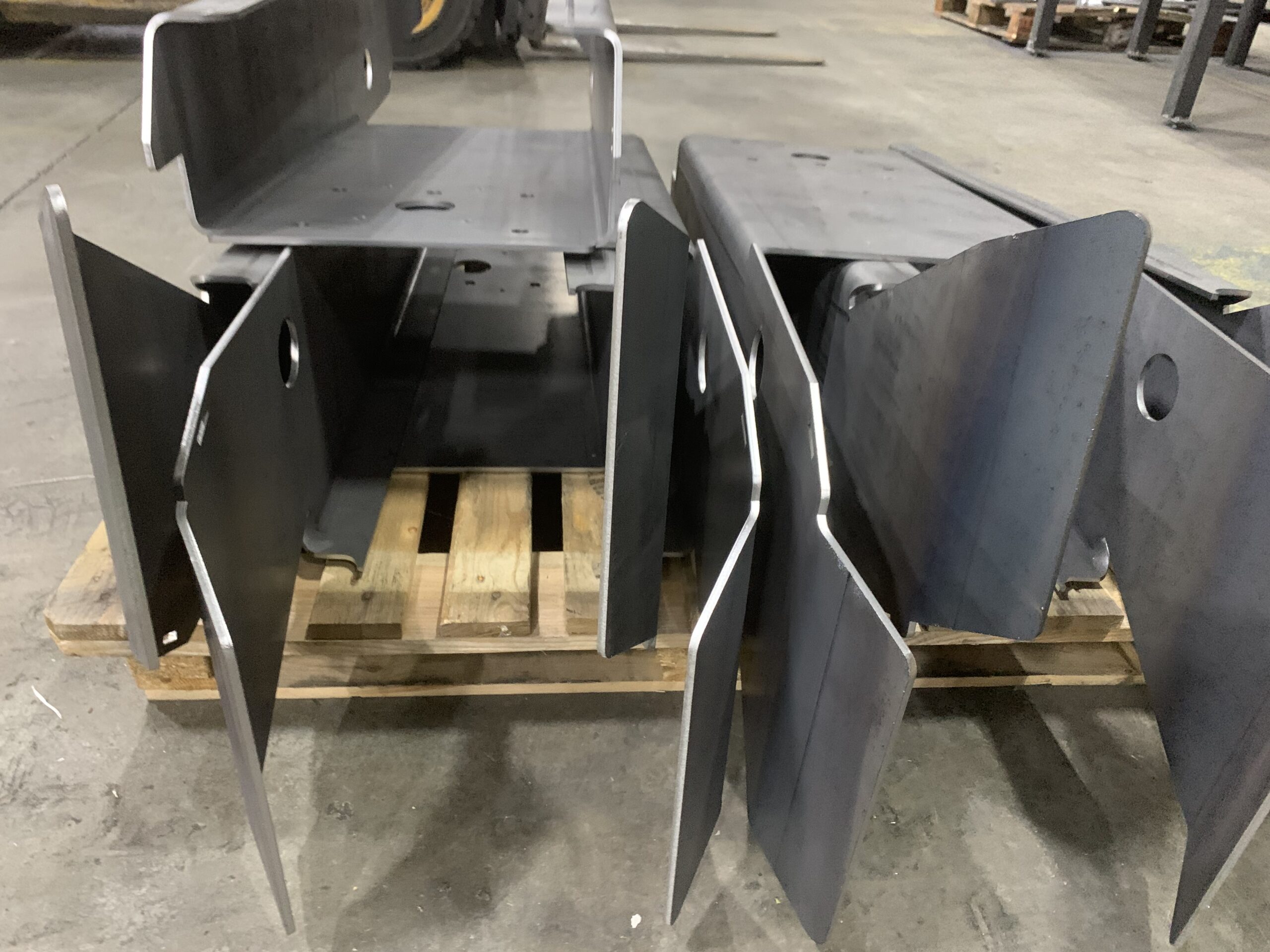

MTL Advanced Ltd is an official SSAB Strenx 700 processor/stockholder for clients around the world. We have the capacity to complete all Strenx laser cutting, bending/folding, fabrication and machining requirements at our 388,000 sq. ft. facility, in Rotherham, Yorkshire, UK.

Strenx 700 Stockholder & Supplier

With various quality accreditations and many years’ experience working with this material, we are able to supply and manufacture Strenx 700 plates in different shapes, sizes and thicknesses to satisfy the needs of our customers.

Due to our extensive in-house manufacturing capabilities, we are able to machine, press parts up to 7.2m length, laser cut and waterjet cut Strenx to the UK’s highest standards. In addition to this, we also offer our expertise in Strenx processing and are more than happy to provide advice and assistance.

What are the benefits of Strenx 700?

With a yield strength of 700 MPa, the product or structure is going to last longer, whereas if a lower strength steel is used the product will not reach it’s full potential.

Upgrading to a steel with higher yield strength leaves room for more high performing designs with increased load bearing capacity. The stresses can be higher which allows for the use of thinner steel, therefore weight can be cut by up to 40% for steel structures and welding time will be reduced significantly.

What is Strenx 700?

Strenx 700 has a minimum yield strength of 650-700 MPa depending on the thickness. This tough material has a much higher yield strength than mild steel.

This material consists of low levels of carbon and has additional grain refiners including niobium, titanium or vanadium. This together with high cleanliness, makes Strenx performance steels the most competitive alternative for cold formed and welded products.

Commitment to Quality