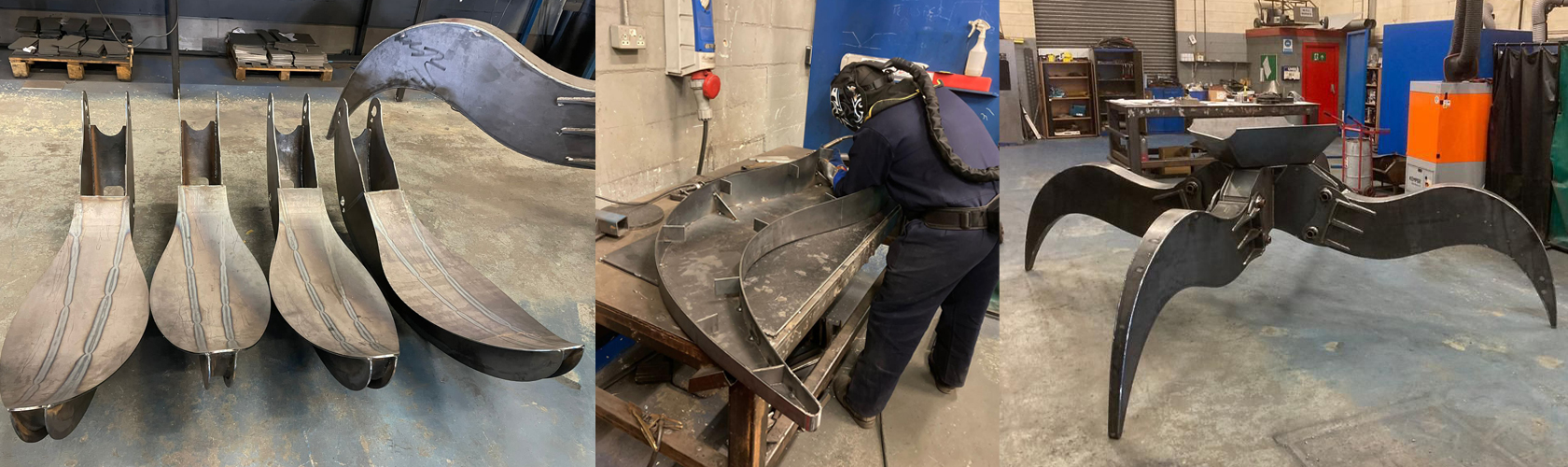

Fabrication & Assembly

MTL is recognised as a leading global metal fabricator and holds an impressive range of approvals/standards for various grades of carbon steels, stainless steel, high strength steel, armoured plate, and aluminium. With over 90 skilled welders and 16 robotic welding cells, we can undertake large volume production for all your fabrication and final assembly needs.

Metal Fabrication & Assembly

Our manufacturing facility offers an impressive 367,000 sq.ft of modern manufacturing space. We have a wide range of modern metal fabrication and assembly equipment and highly qualified engineers and design specialists, with full in-house computer facilities. We offer cost effective, high quality engineering and fabrication services.

MTL has invested in the latest welding equipment and currently has 16 robotic welding cells and various automated welding systems.

Robotic Automation

Ongoing investment in state-of-the-art manufacturing equipment and automation technologies is key to our success. We currently operate four 640-tonne CNC press brakes, one of which is equipped with a robotic handling system that can handle parts up to 600 kg and press materials up to 60mm thick. In addition, we have nine robotic welding cells, further enhancing our production capabilities.

This ensures outstanding repeatability, speed, and precision in our welding and fabrication operations. This advanced setup allows MTL to maintain high production volumes while adhering to the highest quality standards. As part of a recent £10m investment in a new 68,000sq ft Advanced Manufacturing Centre, MTL also recently installed a state-of-the-art fully automated welding line for high volume and complex high strength steel structures.

Why choose MTL?

We constantly invest in the latest industry leading equipment so we are able to fabricate parts to the highest quality standards. This investment allows us to handle high volume and large multi-million pound scale projects for customers in various sectors.

We undertake a wide range of fabrication and assembly projects across many industries. From high volume work to small prototype jobs, we are happy to provide quotations for all work and aim to meet and exceed your personal requirements. We offer a one-stop service, meaning faster lead times, and lower transportation costs overall. From start to finish – MTL can provide a fully comprehensive service.

Trusted to Deliver

Our Manufacturing Capabilities

Laser Cutting

MTL are experts in laser cutting and have become a reputable global supplier of laser cut parts. Starting as a laser cutting company, it has remained at our core as we have gradually expanded to offer a wide range of services.

CNC Machining

MTL is a large scale manufacturing specialist with a wide range of capabilities. We continually invest in the highest quality CNC machinery throughout our facility.

Press Braking/Folding

MTL are experts in laser cutting and have become a reputable global supplier of laser cut parts. Starting as a laser cutting company, it has remained at our core as we have gradually expanded to offer a wide range of services.

Shotblasting

We provide in-house wet painting, shot blasting and powder coating services to a range of industries including defence, rail, automotive, oil and gas, recycling and many more.

Wet Painting

We offer professional in-house wet painting, shot blasting, and powder coating services to a diverse range of industries such as defense, rail, automotive, oil and gas, recycling and many others.

Contract Manufacturing

We provide services to a range of large OEM’s from leading industries including defence and security, construction and quarrying, recycling and rail.

Materials

A range of materials can be competently welded by our skilled workforce such as armoured steels, quenched and tempered structural steels, abrasive resistant steels, offshore grade steels and aluminium (including armoured aluminium). MTL has a dedicated assembly team with many years’ experience in Hydraulic, Pneumatic and Mechanical assembly; our highly skilled workforce allows us to supply complex components fully finished and ready for use.

Specialist Steel

- Hardox®

- Strenx®

- Corten

- Zintec

- Raex

- Hastelloy

- Optisheen

- Cromweld

- Domex

- Titanium

- S690QL

- Copper

- Brass

Armoured Materials

- Armox®

- Mars

- Difender

- Armoured Titanium

- Armoured Aluminium

Mild Steel

- S275

- S355

- S355JR

- S355J2

- S355MC

- Galv/Galvanised Steel

Stainless Steel

- 304 stainless steel

- 316 stainless steel

- Polished stainless steel

- Brush finished stainless steel

- Patterned stainless steel

Aluminium

- Aluminium 1050

- Aluminium 5083

- Aluminium 6082

Ensuring On-Time In-Full Deliveries

At MTL Advanced, we’re continually seeking ways to improve our services and deliver greater value. That’s why we’ve implemented a cutting-edge Barcode Inventory Management System, designed to enhance the quality, speed, accuracy, traceability, and efficiency of our operations. Most importantly, this system enables us to deliver your orders On-Time In-Full, ensuring you get what you need exactly when you need it.

How it directly benefits you:

Implementing this advanced system is a testament to MTL Advanced’s commitment to innovation and efficiency. By leveraging the power of this revolutionary platform, we have enhanced our operational capabilities, reduce costs, and improve service delivery to our clients.

- Faster Turnaround Times: With real-time tracking and precise barcode scanning, we ensure the products you need are always in stock and ready for dispatch, minimising delays and streamlining your experience.

- On-Time In-Full: Ultimately, this system allows us to manage the movement of parts around the business with far greater efficiency. As a result, we can ensure the timely and complete delivery of your orders: On-Time In-Full, every time.

- Enhanced Traceability: Every item is fully traceable from the moment it enters our system, providing full visibility across the supply chain. This helps improve compliance, accountability, and transparency for you.

- Enhanced Accuracy: By automating barcode scanning and data entry, we significantly reduce manual errors. This leads to more accurate inventory records and better overall management.

- Informed, Efficient Decision-Making: Our new system provides detailed reports and analytics, helping us optimise stock levels and strategies to better meet your needs—so you benefit from faster, smarter service.

Commitment to Quality