Recycling

As the largest Hardox® Wearparts Centre in the UK, we have a wealth of experience in manufacturing parts from abrasive resistant and high-strength steels, working on even the most demanding applications for the recycling industry, especially complex fabrications and pressed parts for refuse trucks, including chassis, roof, floor, sides, full bodies, and associated components.

MTL Advanced - Recycling Sector

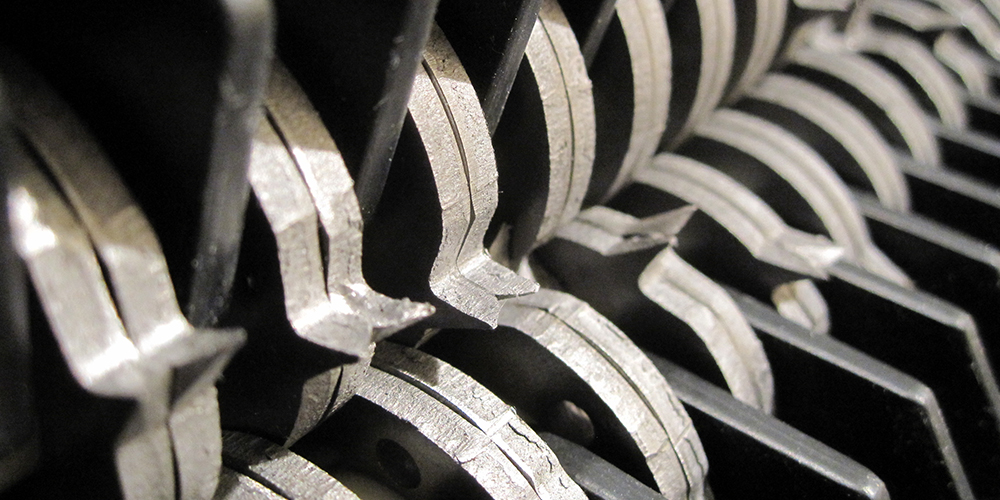

We are able to assist our customers with various requirements, including shredder blades, shear blades, granulator blades, pulveriser hammers and liner plates.

We are one of the few UK companies with the large format laser cutting capability of up to 14m x 3.2m. Our dedicated in-house cutting bay includes the UK’s largest bevel laser cutting machine.

Thanks to recent investments in the world’s largest robotic press braking system, have the capability to bend parts to order in-house, cost effectively with quick turnaround times.

Hardox is the world’s most widely used wear resistant steel plate widely used in the Recycling industry and we are proud to be the UK’s largest Hardox Wearpart Centre.

Thanks to continuous investments in the latest state-ofthe-art technology, we have the capability to machine various High Brinell materials up to, and including, Hardox 600, Hardox HiTuf, Hardox Extreme.

Our impressive range of facilities and stock resources also allow us to supply wearparts to numerous leading scrap recycling operations throughout the UK, including shredder blades, shear blades, screens, pulveriser hammers, and liner plates to name but a few.

Our Sectors

Contact Us Today

Get in touch today about a particular service, process or any specific job.