Domex

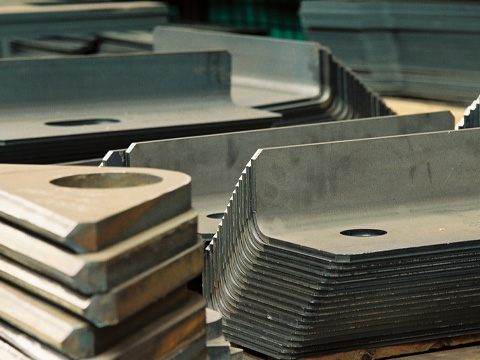

SSAB Domex® includes a broad selection of adaptable structural steels, designed to offer outstanding results in cold forming, machining and welding. Each grade is carefully checked at multiple stages of production to guarantee it meets strict standards for dimensional accuracy and mechanical properties.

Why choose Domex®?

There are many benefits of choosing Domex, including:

- Narrower tolerances

- Consistent product quality

- Improved efficiency in the workshop

- Wider welding process window

- Excellent availability

- Metal coated grades

- Zinc, Galfan and Galvannealed coatings

Domex® Processor & Stockholder

By using Domex® instead of mild steel, you receive a stronger and higher quality product. In which you require less steel, less welding and will lower the weight of your structure, this will also reduce the production cost. Based on previous projects at MTL we have the capability to reduce the manufacturing costs and weight by up to 30%. This is particularly advantageous for use in the automotive industry, where designers aim to keep structural weight low but strength handling levels high.

Using Domex® is an investment due to its high quality, high durability and higher strength in comparison to alternatives. It is less susceptible to damage, saving money long term on repair and replacement costs.

Comprehensive Domex Solutions

SSAB Domex® is produced using exceptionally pure steel. Through a precisely controlled manufacturing process, the material develops a fine grain structure that provides superior mechanical strength and cold-forming performance, a rare quality for a multipurpose structural steel.

Available in thicknesses from 0.4 mm up to 70 mm, SSAB Domex® is highly user-friendly. Its purity and fine grain structure ensure consistent results, along with excellent cutting, bending and welding behaviour in the workshop.

In addition, the impact toughness of SSAB Domex® exceeds the requirements set by European standards, offering greater safety and reliability even in low-temperature conditions.

Cutting Domex/Strenx

Large Format Laser and Bevel Cutting:

XXL Cutting Up to 16m x 3.2m.

Standard Laser Cutting: Up to 6m x 2.5m.

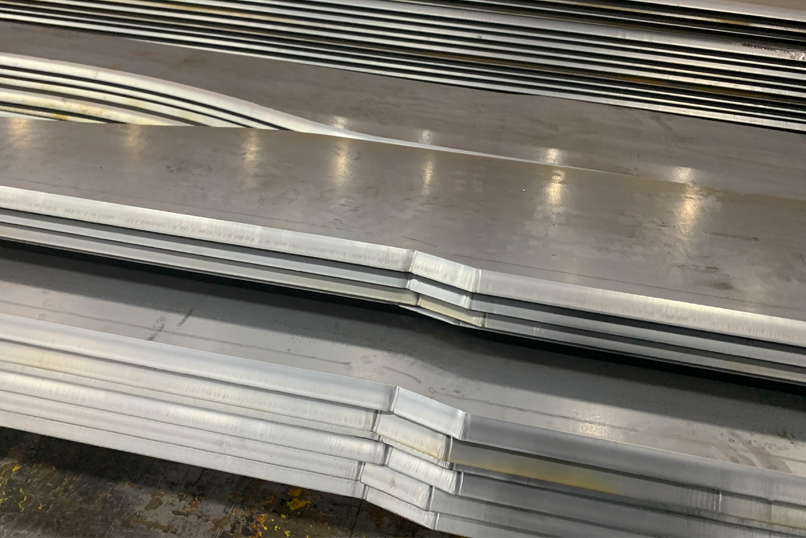

Bending Domex/Strenx

1 x Robotic Press Brake:

XXL URSVIKEN 640 Tonne CNC Press

7.2m wide.

6 x Large Format Press Brakes, up to 640 Tonne: Up to 8m wide.

Welding Domex/Strenx

Welding Domex/Strenx: MTL proudly hold the title of the UK’s first and only Strenx Certified Fabricator. MTL exemplifies excellence in high-strength steel fabrication.

Versatile Welding and Coating Options with SSAB Domex®

Thanks to its purity, SSAB Domex® offers outstanding weldability across all grades, whether using manual or automated methods. The material provides a broad tolerance for heat input and working temperatures, supporting high workshop productivity and shorter lead times. That means no burrs after blanking, punching or slitting, no cracking, no wasted time, no excess scrap, and no production issues.

SSAB Domex® is available as hot-rolled plate, hot- or cold-rolled strip, tubes and sections, and also in metal-coated variants for added corrosion resistance. Options include zinc, galfan and galvannealed coatings, all designed to provide superior paint adhesion.

Zinc coating (hot-dip galvanized): up to 42 μm per side, delivering service life of up to 80 years.

Galfan coating: a thinner 7–23 μm zinc-aluminium layer, combining excellent corrosion resistance with strong weldability and formability.

Galvannealed coating: 6–10 μm zinc-iron alloy coating, ideal for spot welding and premium paint finishes.

We also offer Domex alternatives including:

Commitment to Quality