Press Braking/Folding

We have a wide range of large format CNC press braking equipment, capable of pressing components up to 8m wide. We have invested in 640 tonne CNC press brakes, one of which has a 600 Kg capacity robotic handling system. Operating from a 367,000 sq. ft. modern facility in Rotherham, Yorkshire, we can handle large scale projects and also specialise in the bending or high strength steel and armoured materials.

Press Braking/Folding

Our robotic press braking system is one of the largest installations of its kind in the world and therefore this allows MTL to produce components more accurately, quicker and more cost-effectively than traditional methods.

Our press braking equipment is capable of pressing high tensile materials, forming in multiple positions creating complex shapes. Over the last 25 years MTL Advanced has developed specialist tooling to press high strength steel and wear plate to very tight radii. We also have a wealth of experience bending and pressing armoured materials.

Due to our large capacity, we can offer a wide range of services to our customer base, from one off prototypes to high-volume production runs all with a fast turnaround.

We utilise the latest CNC technology to enable us to manufacture detailed components whilst the press brake monitors and adjusts the bending force to guarantee that the bend is consistent across the length of the material.

Robotic Automation

Ongoing investment in state-of-the-art manufacturing equipment and automation technologies is key to our success. We currently operate four 640-tonne CNC press brakes, one of which is equipped with a robotic handling system that can handle parts up to 600 kg and press materials up to 60mm thick. In addition, we have nine robotic welding cells, further enhancing our production capabilities.

This ensures outstanding repeatability, speed, and precision in our welding and fabrication operations. This advanced setup allows MTL to maintain high production volumes while adhering to the highest quality standards. As part of a recent £10m investment in a new 68,000sq ft Advanced Manufacturing Centre, MTL also recently installed a state-of-the-art fully automated welding line for high volume and complex high strength steel structures.

Why choose MTL?

At MTL Advanced, we provide precision press braking services using advanced CNC-controlled press brake equipment and a skilled team. With experience in working with a wide range of materials (including high strength steels and armoured materials) and complex geometries we deliver accurate, high-quality results. We focus on customisation and collaboration to meet specific project requirements, while maintaining a strong commitment to efficiency and quality. Our approach is built on innovation and sustainability, making us a trusted partner for your press braking needs.

Trusted to Deliver

Materials

MTL is recognised as a world leader in cold forming steel and aluminium plate, particularly when forming Hardox, armoured steel and armoured aluminium. The process involves zero heat input and does not affect mechanical properties.

Specialist Steel

- Hardox®

- Strenx®

- Corten

- Zintec

- Raex

- Hastelloy

- Optisheen

- Cromweld

- Domex

- Titanium

- S690QL

- Copper

- Brass

Armoured Materials

- Armox®

- Mars

- Difender

- Armoured Titanium

- Armoured Aluminium

Mild Steel

- S275

- S355

- S355JR

- S355J2

- S355MC

- Galv/Galvanised Steel

Stainless Steel

- 304 stainless steel

- 316 stainless steel

- Polished stainless steel

- Brush finished stainless steel

- Patterned stainless steel

Aluminium

- Aluminium 1050

- Aluminium 5083

- Aluminium 6082

MTL ADVANCED

Design for Manufacture

Our Design for Manufacture team, with over 25 years of expertise, uses the latest design and simulation software, such as Catia, Solidworks, and Inventor.

We can optimise a customer’s design to reduce the amount of weld; this is particularly advantageous in the defence sector as it has many safety benefits. A component can be made lighter, stronger and at a lower cost through eliminating any unnecessary welding.

Our Manufacturing Capabilities

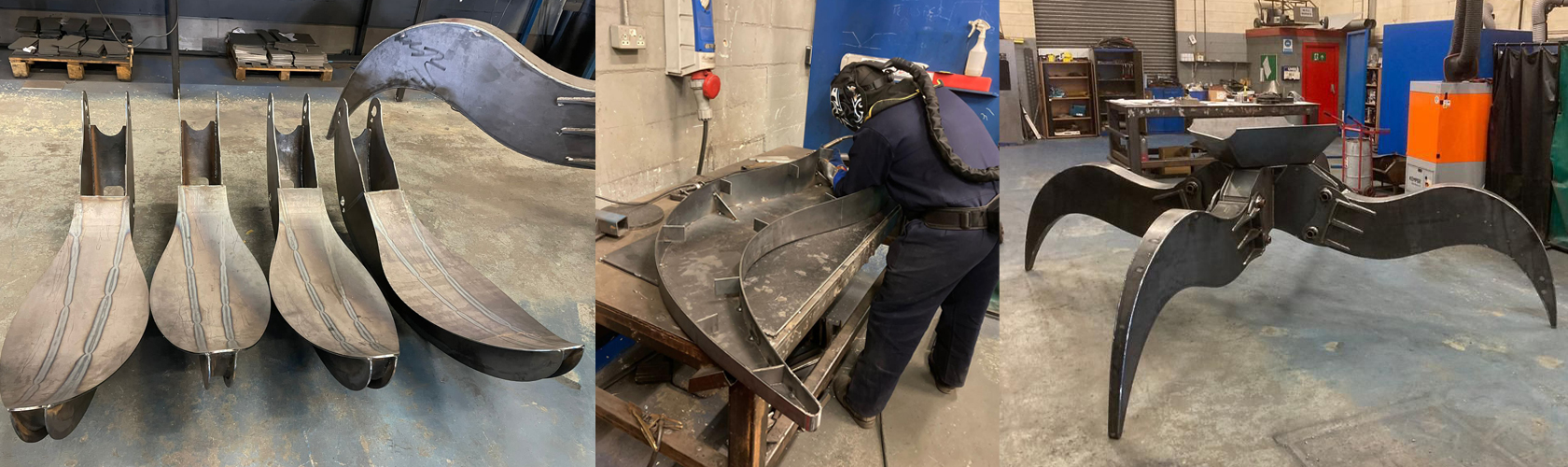

Fabrication & Assembly

MTL is recognised as a leading global supplier of fabricated components and holds an impressive range of approvals/standards for various grades of carbon steels and aluminium.

Laser Cutting

MTL are experts in laser cutting and have become a reputable global supplier of laser cut parts. Starting as a laser cutting company, it has remained at our core as we have gradually expanded to offer a wide range of services.

CNC Machining

MTL is a large scale manufacturing specialist with a wide range of capabilities. We continually invest in the highest quality CNC machinery throughout our facility.

Shotblasting

We provide in-house wet painting, shot blasting and powder coating services to a range of industries including defence, rail, automotive, oil and gas, recycling and many more.

Wet Painting

We offer professional in-house wet painting, shot blasting, and powder coating services to a diverse range of industries such as defense, rail, automotive, oil and gas, recycling and many others.

Contract Manufacturing

We provide services to a range of large OEM’s from leading industries including defence and security, construction and quarrying, recycling and rail.

Commitment to Quality