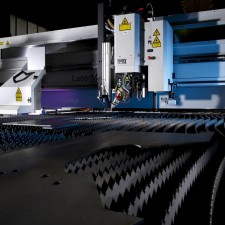

Rotherham based contract manufacturing specialists MTL Advanced have recently commissioned a new 4 x 2m fibre laser cutting machine with fully automated loading.

This new TruLaser 5040 fibre laser cutting machine is the second addition of its kind in the past 9 months and is part of the company-wide investment and expansion plans for 2018 following the award of multiple multi-million contracts for their blue-chip OEM customer base.

Karl Stewart, General Manager of MTL Advanced, said: “This new investment in state-of-the-art technology will enable us to take on more business and improve our service and lead times to customers. We are focused on expanding our customer base to fuel our company’s continued success and have recently started a major recruitment drive to create 59 new positions in order to consolidate our position as a leading contract manufacturing business“.

The 8KW 5040 Trumpf TruLaser comes fully fitted with an automated LiftMaster and is one of the fastest laser cutting machines in the UK, offering high speed nitrogen cutting on a large range of materials as well as the ability to cut up to 40mm stainless steel, 25mm mild steel and aluminium. The machine also has the ability to cut copper and brass up to 10mm.

Head of Sales, Michael Ellmore added: “Investment into the latest technology, such as the addition of this new fibre laser cutting machine, is a vital part of our plans for continued growth as it enables us to increase productivity across the entire parts spectrum and maintain our commitments to providing the highest quality turnkey service.

The new laser takes the total of laser cutting machines at our Rotherham site to 8, and 26 in total within our whole Group, which indisputably makes us one of the largest laser cutting operations in Europe. ”

To find out more about our laser cutting services and capabilities, please visit our designated page here.